- Home

- About

- Products

- Stainless Steel Sheet & Plate

- 17-4 PH Stainless Steel Sheet Plate

- 303 Stainless Steel Sheet & Plate

- 304 Stainless Steel Sheet & Plate

- 304h Stainless Steel Sheet & Plate

- 304l Stainless Steel Sheet & Plate

- 309 Stainless Steel Sheet & Plate

- 309H Stainless Steel Sheet & Plate

- 309S Stainless Steel Sheet & Plate

- 310 Stainless Steel Sheet & Plate

- 310H Stainless Steel Sheet & Plate

- 310S Stainless Steel Sheet & Plate

- Stainless Steel Sheet & Plate 316

- 316h Stainless Steel Sheet & Plate (UNS S31609)

- Stainless Steel Sheet & Plate 316L

- 317 Stainless Steel Sheet & Plate

- Stainless Steel Sheet & Plate 317L

- 317LMN Stainless Steel Sheet & Plate

- 321 Stainless Steel Sheet & Plate

- 321h Stainless Steel Sheet & Plate

- 347 stainless steel Sheet & Plate

- 347H Stainless Steel Sheet & Plate

- 410 Stainless Steel Sheet & Plate

- Stainless Steel Sheet & Plate 410S

- 904L Stainless Steel Sheet & Plate

- Stainless Steel Plate SSC-6MO

- Duplex Stainless Steel Sheet & Plate

- Nickel Alloy Sheet & Plate

- Titanium Plate

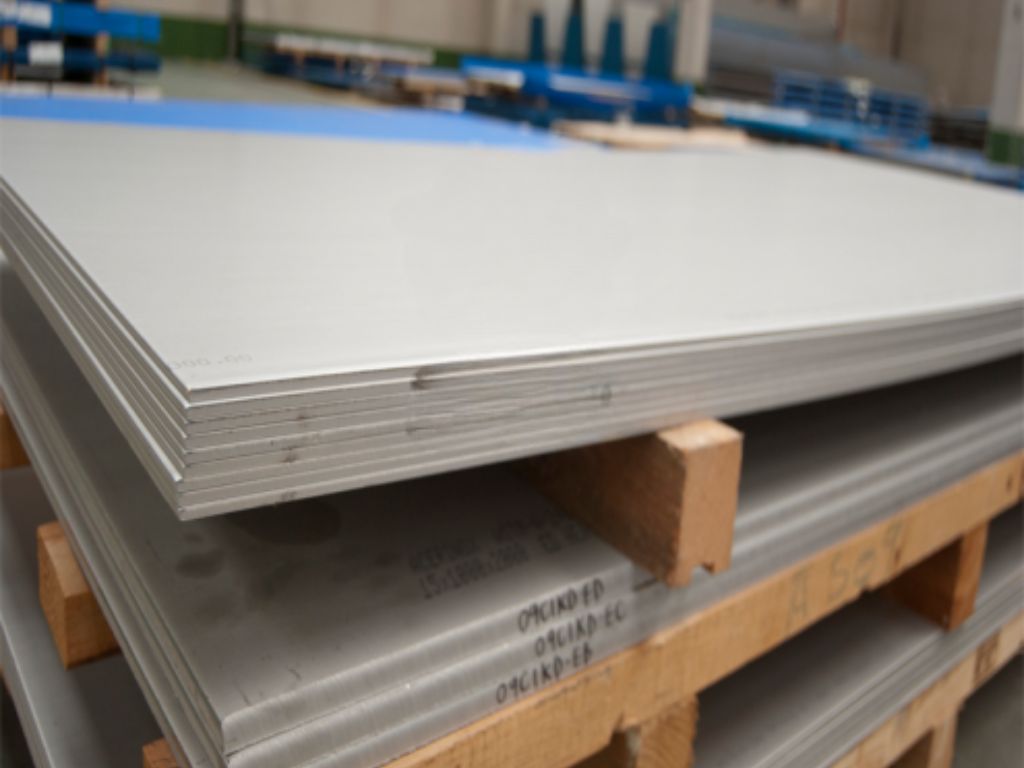

- Stainless Steel Sheet & Plate

- Industries

- Blog

- Contact Us